Fabric printing has been regarded as a stand-out growth area for some time. One area of particular growth is textile-based display pieces, with the opportunities for work being plentiful for those active in the sector.

However, with these opportunities comes intense competition, with plenty of print companies vying for the most profitable jobs and long-term relationships with valuable customers. This begs the question: how can you gain a real advantage in what is a busy yet opportunity-heavy market, without having to cut your costs?

One of the most effective ways to stand out from the expanding crowd is to ensure you are delivering high quality work on each project. To do this, you need to make sure your production equipment is up to date and performing at its optimum level. This may require new investment, but before getting too far ahead of yourself, it is important to first consider the options available.

Doing things the dye sublimation way

Traditionally, the primary technology associated with textile printing has been dye sublimation, a process that has been around since the mid-1950s. It uses water-based dye inks which, when heated to between 190°C and 205°C, turn into gas and bond with the receptive surface.

Dye sublimation comes in two forms. The first is transfer printing, where the image is printed onto paper first and then transferred onto fabric using heat. The second is direct-to-fabric printing, where ink is applied straight to the fabric and then fixed using heat or steam.

For some, this is the ideal approach as the material and ink costs are usually lower than with other methods, making it suitable for more standard work such as soft signage, promotional merchandise and short-run apparel. Dye sublimation also allows users to create lightweight graphics that are easy to fold, ship and install, while delivering vibrant colours. This has fuelled its popularity, surpassing that of heavier, more rigid display materials.

However, dye sublimation does have its limits. The material you are applying the design or graphics to must contain polyester, nylon, acrylic, or be treated ceramic, with inks only binding to compatible surfaces. Colour consistency and repeatability can also be difficult due to the two-step transfer process, while the heating requirements mean energy costs will likely be higher.

While sublimation inks will for the foreseeable future remain the most appropriate technology for garment and low-end flag printing, there is now an alternative for those high-end, high-value and – above all – high margin display applications.

Upping the ante with UV

A brief tech overview: while dye sublimation inks penetrate the threads of the fabric and to all intents and purposes become part of the fabric, UV-inks sit on top of the fabric. For visual communications, this can be an advantage as colour density and colour vibrancy – especially with regards to backlit displays – are much more effective and impactful when using UV inks.

When investing in UV-curing technology, print service providers can still print onto all the traditional media (banner and vinyl), but this is then enhanced by the ability to print onto fabric for high value added backlit and blackback displays.

It’s true to say that up until now, UV printing has faced some limitations with regards to fabric applications. Colours have lacked depth without double striking and inks have often been brittle, making them unsuitable for textiles that require folding or stitching.

Enter Fujifilm which has sought to address these issues with the development of UVijet ink. Using a unique pigment dispersion technology, UVijet features a higher concentration of pigment, forming an ink film that delivers vibrant colours without the need for double striking. These inks are also considerably more flexible than older formulations, opening up their use in textiles and fabrics that will be stitched or folded.

UVijet also addresses concerns over the sustainability of UV inks, with the end-of-life recyclability of prints from both technologies generally comparable. In addition, more than 90% of UV ink is used in the final print, compared with just 50% in dye sublimation due to evaporation during the heat-based transfer process. This results in better ink yield and efficiency, reduced waste and improved overall ROI, further closing the environmental gap between the two technologies.

Technology in action

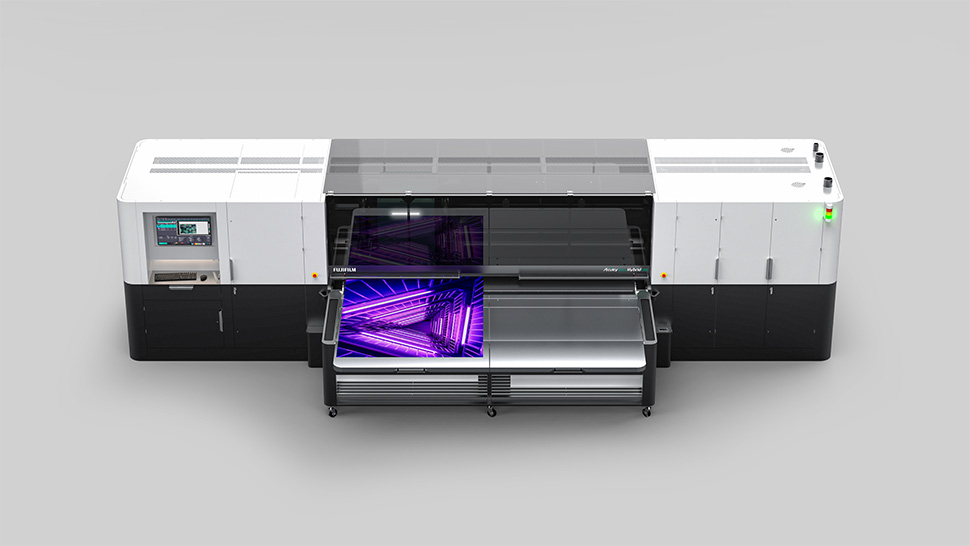

An example of these new-age UV inks in action, is in the Acuity Ultra Hybrid from Fujifilm. Featuring Kyocera print heads, the machine allows print service providers to produce bright, eye-catching and photographic-quality output across a range of materials. This enables access to profitable opportunities in areas such as retail, exhibitions and high-end display graphics.

Looking ahead

None of this is to say that dye sublimation has had its day, or that UV is now the only technology worth considering in textile production. Dye sublimation remains a highly effective option for creating vibrant, short-run fabric-based applications. But advancements in UV inkjet are allowing printers to push the boundaries of what is possible with flexible, fabric-based applications. Pairing ink such as Fujifilm’s UVijet with advanced hardware solutions such as the Acuity Ultra Hybrid will open doors across many exciting, and profitable, markets.

Authored by Shaun Holdom, Global Business Development Director, Fujifilm