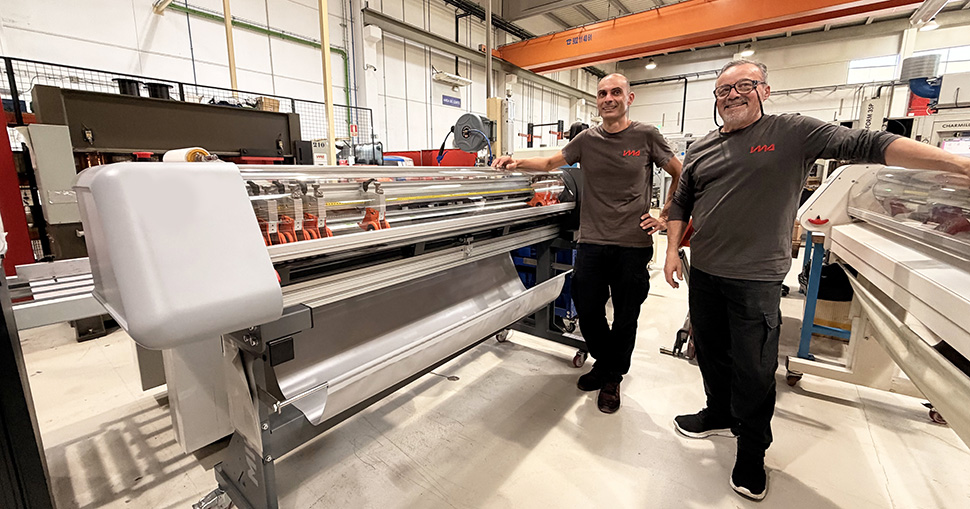

IMA, a Spanish company specializing in the production of magnetic materials for industrial applications, has chosen Flexa Miura automatic cutter for the second time, confirming its trust in a technology that ensures precise cuts and consistent productivity.

The company works daily with magnetic rubber rolls, a material that requires extremely accurate and clean cuts. Choosing the right cutting equipment is therefore strategic: precision, reliability, and robustness are essential to achieve excellent results throughout the entire production process.

The first Miura: 2017

Before installing the Miura, IMA performed the cutting process manually, which led to long processing times and a high risk of errors and waste.

“In 2017 we installed our first Miura automatic cutter for cutting magnetic rubber,” says Ricardo Altimira, owner of IMA. “From the very beginning, the results were excellent, with cutting precision beyond expectations and smooth operation.”

The second investment: 2025

The positive experience with the first machine convinced IMA to invest again in Miura technology in 2025.

“The Miura is precise, requires virtually no maintenance, and allows us to save time. The new model installed in 2025 is even more powerful and can cut thicker materials, further expanding our production capabilities.”

Tangible benefits

IMA chose Flexa for its solid reputation in the industrial cutting sector and the proven quality of its products. The introduction of the Miura has transformed IMA’s production process: increasing capacity, reducing processing times, and ensuring highly precise automatic cutting of magnetic rolls, with reduced waste and greater efficiency.

“I would recommend it to anyone looking for an easy-to-use, accurate, and reliable machine. In three words? Good, simple, reliable.”