You’re not imagining it – hybrid printers are in high demand.

In fact, according to IMI Europe, over the last two years, hybrid printer sales in Europe outnumbered those of 5m and 3m roll-fed, and flatbeds.

Recognised by some as the ‘Swiss army knives of printing’, these low footprint, multi-use machines have rocketed in popularity, relatively quickly. Why is this?

Changing times

In addition to the post-Covid ‘hybrid working patterns’ we’re all familiar with, one could argue that hybrid printers are another outcome of the pandemic.

When the pandemic hit – some print markets fell away dramatically, while others remained stable or even grew. PSPs – even those who had been very specialised in the past – were forced to pivot into other markets, and other applications. Many proved themselves to be remarkable entrepreneurs, moving into entirely new market verticals which they continue to operate in to this day.

An increasing number of printing companies operating in the wide format sector now pitch for ‘universal work’ – backing themselves to deliver everything from vehicle decoration, to window graphics, to retail displays, billboards and building wraps. This shift to a more diverse product offering has driven a requirement for much more versatile equipment.

From a cost perspective, it just makes sense for businesses to invest in a multi-purpose hybrid machine to boost their printing technology portfolio, rather than numerous higher-value printers that can handle a comparatively smaller number of applications.

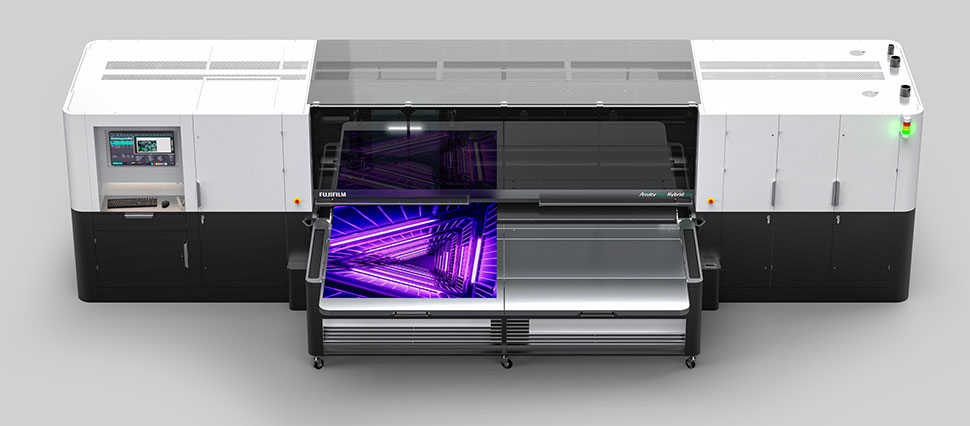

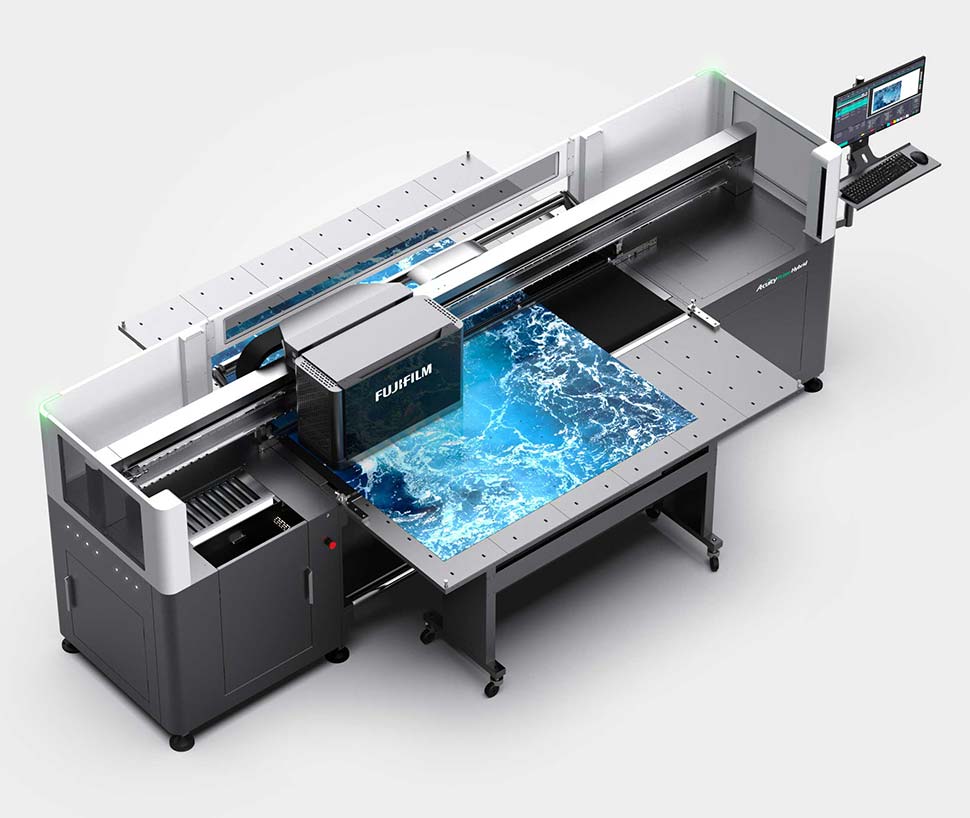

Fujifilm Acuity Ultra Hybrid LED

Better tech

Fortunately, inkjet printing technology has now improved to the point where reliability is no longer compromised with hybrid machines.

When hybrid printers first hit the market in in the early 2010s, issues such as cracking ink or poor adhesion were commonplace. This was partly due to limitations surrounding the mercury curing process.

Thanks to the development of better printhead technology and UV LED curing, such issues have been managed and minimalised – particularly with the new Fujifilm Acuity Ultra Hybrid LED and Acuity Prime Hybrid printers (both launched in 2023).

Advances in ink technology have also played a pivotal role in the progression of hybrid printers. Fujifilm has decades of UV ink and inkjet expertise and its hybrid machines were only made possible through its highly versatile high performance inks.

Fujifilm is able to demonstrate on flexible media, including fabrics, that its ink is truly flexible – free from cracks and breaks while still printing at exceptionally high levels of quality. Our inks also have excellent adhesion, even on low energy surfaces such as plastics, polyester and polypropylene.

In addition, media transport systems have evolved tremendously – from mesh conveyor belts with clips to features such as intelligent vacuum systems with sensors – further leading us to the popular hybrid machines seen on the market today.

What’s next?

I believe hybrid printers will continue to be the market leaders for some time.

In terms of advancements, at some point we are likely to see the development of all-encompassing ‘superwide’ (5m) hybrid printers. Currently, these widths of hybrid machines do not exist, so there is a gap in the market.

The speeds at which hybrid machines can print will improve too. At Fujifilm, for example, we’re already working on speeding up our machines by adding additional printheads.

We’re also investing in our media transportation systems. There will be increased automation – for the pick-up and drop-off of sheets, and adding reels to the chassis, for example – which will speed up productivity and the material switching process for printers, as well as the versatility of the machines.

Ultimately, the quicker printers and processes become, the less humans will be able to keep up with them. So human intervention will become the weak point in the production line. If, for example, a machine is running 100-200 boards per hour, it will need two or three people to run it – unless automotive features are brought in to provide that support.

It will be interesting to see how, in the future, the market landscape for these popular machines develops.