There is no doubt that the textile printing market, both in the UK and around the world, is continuing to flourish and grow. It is being driven by advancements in a trilogy of technologies – printers, finishing equipment and textiles. Output that was previously unable to be digitally printed is now achievable and is opening up opportunities for print companies to produce all manner of innovative and creative pieces.

While this rapidly growing market is exciting, companies wanting to excel in textile print for the first time must first look at the tools they need to succeed.

First up is your printer; what machine do you need? There are plenty of printers available on the market, so how do you know which one is right for you? Start by understanding the type of applications that you want to create and the markets you want to target. Use this application and market knowledge to select the most suitable hardware and marry this with the correct ink technology.

At Soyang Hardware, we offer a variety of advanced printers tailored for textile applications, such as the new Mimaki TS330-3200ds dye-sublimation printer with exceptional print quality and versatility. It is ideal for producing vibrant soft signage, sportswear, and fashion garments. Additionally, the Fujifilm Acuity Ultra R2 3.2m and 5m LED UV printer provides reliable and high-volume solutions for high-quality, durable graphics.

Soyang Hardware offers a variety of printers tailored for textile applications, such as the new Mimaki TS330-3200ds dye-sublimation printer and the Fujifilm Acuity Ultra R2 3.2m and 5m LED UV printers.

Also, relating to hardware, companies must look at the type of finishing equipment needed to produce the chosen applications. This is just as important – if not more so – than the printer choice. Given the huge advancements in finishing technology and the many new capabilities, it’s this area that drives efficiencies, removes many bottlenecks and makes a huge difference to the bottom line.

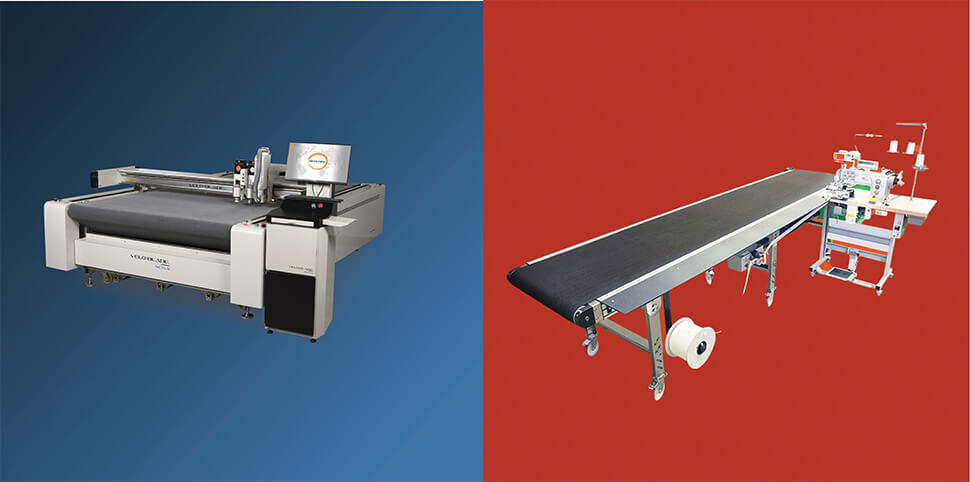

On this front, Soyang Hardware is able to provide industry-leading finishing options such as the Vivid Veloblade range, designed for precision cutting, creasing, and laminating, enhancing productivity and application quality. Additionally, Soyang supplies and supports Solent Texsew Pro sewing machines in the UK and Ireland which ensure seamless finishing for textiles ranging from flags to exhibition graphics.

Soyang Hardware provides industry-leading finishing options such as the Vivid Veloblade range and Solent Texsew Pro sewing machines

Finally, think about what sort of materials you will be working with. There are many types of textiles available, but not all are suitable for every application. Carefully consider the work you will be producing and research the most suitable material for the project. Remember that the technology of both the raw textiles and the coating used have developed dramatically in recent years. Talk with suppliers who are experts in this field and can offer you advice and guidance. Also, check whether your material of choice is compatible with both your printing and finishing hardware.

Sustainability will become an increasingly important aspect of printed textile work, and those planning to move into the sector should keep this in mind if they are to succeed in the long term.

Accordingly, at Soyang Europe we have a particularly strong focus on environmentally friendly solutions and currently offer seven textile products made from recycled PET yarns and also seven different PVC-free alternative solutions to traditional banner products.

Of course, picking out the right textile amid a sea of options is easier said than done. To aid you in your quest, there are several factors to keep in mind: the quality and stability of fabric, the environmental impact of creating this material, and how this will reflect on your own sustainability strategy.

Importantly – for efficiency and to meet tight turnaround times – you need to be sure that your supplier has the space to hold their complete range in stock and the ability to ship on demand nationwide, which is something we focus on at Soyang Europe. We don’t just stop at that though; we are continuously working with our factory to introduce more lines to meet the changing demands in the textiles market.

As such, we are well placed to deliver on such variables, offering a wide range of textiles, printers and finishing solutions to meet demands across all kinds of applications and project types.

Authored by Shane Furness, Procurement Director at Soyang Europe

For more information on Soyang and the solutions detailed above, please visit www.soyang.co.uk.