The company, a leader in variable data integrity and print quality inspection for the packaging, labels, and commercial print industries, is presenting a full suite of integrated, tailored solutions to help customers in all segments of the graphic communications market, to produce error-free printing, automate inspection requirements and reduce waste to drive profitable growth.

Lake Image Systems will feature its latest portfolio of powerful solutions for Document producers, Label printers and Packaging converters to automate variable data integrity and print quality inspection requirements. Four industry applications zones will be demonstrated at the show. These include:

- Zone 1: Digital Packaging: With variable data, digitally printed on packaging is on the increase, Lake Image will be showcasing its latest range of solutions for reading, grading and verifying barcodes, QRcodes and text elements as well as for detecting print defects such as streaks, hickies & voids and print registration issues for a variety of flexible packaging applications

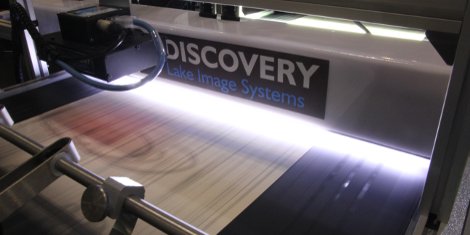

- Zone 2: Variable Data Labels & Security Printing: Variable data and barcodes on labels such as tax stamps, pharmaceutical and authentication labels are now critical for many anti-counterfeit and traceability applications such as track and trace systems. Similarly, many security documents and paper have unique identifiers which need to be tracked and verified to prevent criminal activity and ensure process integrity during complex, multi-step production processes. Lake Image will demo its industry winning Discovery MaxScan solution for inspecting, reading, tracking and verifying variable codes on a variety of challenging substrates including highly reflective tax stamps for out of sequence, missing or duplicate labels as well as for positional and print defects issues. The Lake Image Discovery software tools provide 100% quality inspection and print data integrity for all label presses and applicators at speeds exceeding 300 metres per minute.

- Zone 3: Transactional and Direct Mail: The full Discovery platform will be demonstrated, including a comprehensive range of verification, inspection and integrity software tools to ensure mission critical documents and mailings are always 100% correct. Sequence check, data matching and presence/absence software tools provide variable data verification from page to page printing including duplex operations. Inspection tools detect print defects such as print registration, colour deviation and print quality. Integrity tools such as Batch Control, File Audit and File Look-Up, verify that each and every printed page is produced with the highest levels of integrity compared to the original customer data job files. Discovery tools can be invoked conditionally by detecting triggers in the data, an image or a code printed on the document. Combining multiple tools enables complex inspection tasks to be performed when required and is saved with the specific job.

- Zone 4: Loyalty, Gaming & Plastic Cards: A variety of inspection solutions will be on display including card number verification, missing/duplicate card detection, scratch off verification, pin number legibility, pin & account number reporting, sorting/batching and database integrity reporting. Other requirements such as card/carrier matching & magnetic stripe reading are also available.

“Drupa is an important event for us, and offers the perfect stage to present our full portfolio of solutions for improving print quality, variable data integrity and waste reduction, and illustrates our commitment to working with our customers to grow their businesses” commented Martin Keats, Managing Director at Lake Image Systems Ltd. “We will be demonstrating our broadest array of industry targeted solutions ever which effectively addresses all the inspection needs for today’s blended conventional and digital production environments, Our application and technology experts will be on the stand throughout the show to ensure visitors get all the information they need.”