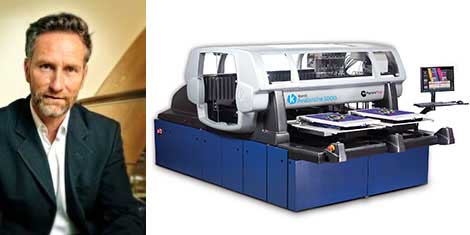

Frazer Chesterman, Director at FM Brooks and LFR guest blogger, talks about the highlights at the recent Unitex 3rd International Digital textile conference…

Last week, I attended the excellent Unitex 3rd International Digital textile conference at University college, Gent entitled: ‘The Change is clear from Analog to Digital.’

The afternoon session on day one – hosted by John Scrimshaw of WTIN – was all about industrial print. The key focus was on two aspects that are re-shaping the textile print industry: that digital print is going industrial; and that there is a trend in ‘re-shoring’ – the return to Europe of printing on textile.

Speakers from Mimaki, SPGprints, Sensient, Reggiani and Zimmer all talked about general trends and new developments in digital textile machines in industrial applications which sees a transition from short-run sampling to high-speed mass customisation.

However, the presentation that resonated with me was the one by Omer Kulka of Kornit Digital who talked about a couple of new products and then went on to explain more about the trend towards re-shoring and particularly the return of production to Italy.

Kornit Digital highlighted two key members of its new digital textile portfolio – Kornit Avalanche 1000 and the Kornit Breeze.

The Avalanche 1000 is Kornit’s fastest industrial t-shirt and garment printer, while the Breeze is an entry-level machine. Both the machines incorporate Spectra Polaris printheads. The Avalanche 1000 employs 24 printheads and the Breeze six, with 256 nozzles per head. The overall printing area for Avalanche is 60x90cms and Breeze is 35x45cms.

Both the machines are based on Kornit’s NeoPigment ink process, the only technology that print on multiple fabrics, dark and white with no pre-treatment or post-print press required, claims the company.

Their breakthrough in DTG solution offers businesses not only superior print quality and reliability, but also the ability to customise, organise and manage their valuable design assets, orders and inventory, thus enabling them to capitalise on new market opportunities for increased profit and growth.

So what do they mean by new markets ? Well 20 years ago the trend in textile print and production had gone offshore away from the key consumer markets towards cheaper mass production locations – for example a shift towards production in China, India or Central/South America.

However, broad developments in the digital print technology and shifts in consumer demand towards fast fashion and ‘I want it now’ demands of the younger IPAD generation of consumers means that where possible if we can print and produce closer to the customer, we reduce down cost and time and respond to consumer demand quickly and ever changing tastes.

In particular, the fashion industry demands the quick turnaround that Inkjet can offer and this is effectively changing the market. A number of our InPrint 2014 exhibitors had previously endorsed this trend that I observed again last week in Gent. Alessandra Borghi at Kiian Digital Inks explained to me in April in Hannover: “For retailers like Zara, they need to be able to respond to fashion tastes far more locally, and in line with a constantly evolving landscape. So mass production, that is quite slow to respond and that has a general approach, does not provide retailers with the right local style or response time they need.”

Tim Phillips from Xennia also highlighted the advantages of Inkjet for the textile printing industry in reducing the risk of getting it wrong, avoid the huge costs in time and money of making mistakes whilst opening up a sea of new creative potential. Getting the design or colour wrong on a clothing print run could be a commercial disaster, inkjet allow you greater flexibility to avoid such calamity.

Perhaps a revolution is on the horizon, certainly there is a sense that the fashion and textile printing world is getting excited by digital!

About Frazer Chesterman:

Frazer Chesterman is Co-owner and Director of FM Brooks, the new event business behind EcoPrint Live 2012 and InPrint 2014. The second InPrint Live event is scheduled for November 2015 in Messe Munich. For more information on the event, please visit www.inprintlive.com