Business News

Siegwerk, one of the leading global providers of printing inks for packaging applications and labels, complements its broad ink and service portfolio for printers and converters by offering its cross-application ink and packaging expertise also directly to brand owners.

The Fogra Research Institute for Media Technologies recently assessed the ultra-high-speed, single-pass EFI Nozomi C18000 LED inkjet corrugated printer from Electronics For Imaging, Inc. according to the ISO 20690 energy standard and determined it to be the leading single-pass corrugated production device in terms of power consumption efficiency.

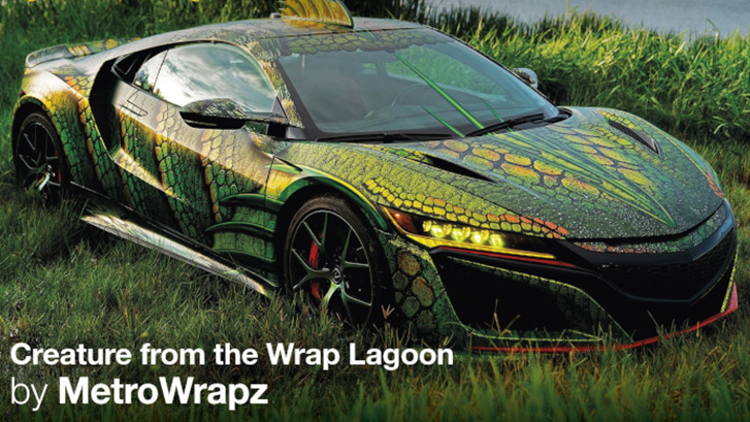

Avery Dennison Graphics Solutions announced today that MetroWrapz of Hollywood, Florida, has earned the “King of the Wrap World” title for the second consecutive year.

Throughout November and December 2019 i-Sub will be hosting VIP days at Agfa’s HQ in Antwerp, Belgium.

Epson today announced Trigon Imaging Solutions has opened its Epson Certified Solution Center in Milford, Ohio, outside of Cincinnati.

The IPIA has laid a new corner stone of its growth strategy by creating a ‘Lite’ membership category, which opens a key segment of the trade association’s benefits up to a much wider spectrum of the commercial print industry.