In today’s print industry, balancing quality, efficiency, and environmental responsibility is an increasing priority. With ongoing pressure on margins and growing sustainability expectations, technologies that improve production efficiency without sacrificing output quality are more relevant than ever.

Optimising Ink Usage Without Compromising Output

Ink remains one of the most significant ongoing costs in print production. Technologies that reduce consumption while maintaining visual quality can therefore deliver measurable long-term benefits. Mimaki’s Ink Saving functionality, available on select models, addresses this challenge by intelligently adjusting colour profiles and ink densities in a controlled, automated way.

Users can select from five Ink Saving levels, offering approximately 10% ink reduction at Level 1 and up to around 50% at Level 5, depending on the application and required output quality. This approach enables print providers to lower ink usage while preserving colour fidelity, ensuring consistent results that continue to meet customer expectations.

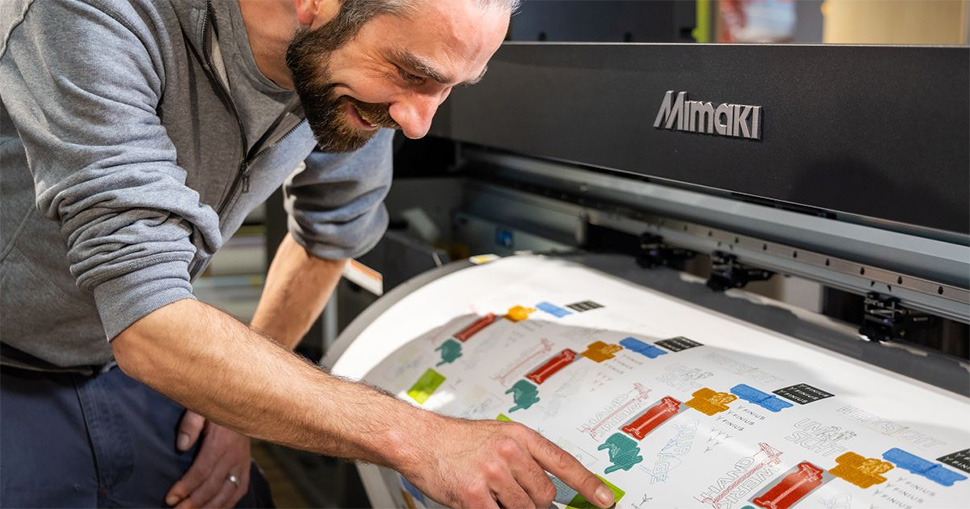

Markus Jürgensen, owner of Print and More, operates a Mimaki CJV200-130 and regularly uses the Ink Saving function to improve production efficiency. “We make good use of the ink saving option, usually at level 3,” says Markus. “At around 30% ink reduction, it works very well for us without any compromise to quality.”

Integrated Ink Saving Streamlines High-Volume Production

The Ink Saving tool is fully integrated within Mimaki’s RasterLink7 RIP software, allowing users to select the appropriate ink reduction level based on job requirements. Once applied, the setting requires no additional steps or workflow changes, ensuring efficiency gains are achieved without adding operational complexity.

This level of integration is particularly valuable in fast-paced production environments with high print volumes or short turnaround times, such as Print and More, where rapid output is often essential.

Sustainability as a Practical Outcome

In addition to economic benefits, reduced ink consumption supports more environmentally responsible printing. Lower ink usage results in fewer cartridges being consumed and disposed of, helping to reduce material waste and associated emissions. While not a standalone sustainability solution, it represents a practical step towards more sustainable day-to-day production. UK distributor, Hybrid Services has offered a rebate linked solvent cartridge recycling scheme since 2008, offering customers the opportunity to manage their print waste whilst being rewarded with free ink.

As environmental regulations continue to evolve and customers increasingly prioritise responsible suppliers, features such as Mimaki’s Ink Saving functionality and Hybrid’s Let’s Do MORE! Scheme offer print providers tangible ways to align with wider industry expectations.

BS4 Inks and Ink Saving Combine for Greater Cost Control

Beyond the built-in ink saving feature, Mimaki’s latest solvent ink option, BS4, provides an additional opportunity to reduce running costs. “Opting for Mimaki BS4 inks can significantly reduce consumable expenditure,” says Andrew Edwards of Hybrid Services. “When combined with the easy-to-use Ink Saving functionality, it delivers a meaningful reduction in ink spend, while retaining the long-term warranties associated with Mimaki’s latest solvent printer range.”

In an increasingly competitive market, Mimaki’s Ink Saving technology gives print providers greater control over costs without compromising output quality. By combining efficiency, sustainability, and consistent results, it enables businesses to operate more profitably while continuing to deliver the high standards their customers expect.