LFR / Consumables / Page 50

Ink

Following its recent launch of neon inks for UV printing, swissQprint now highlights the scope that these fluorescent colours open up. With just two inks, four striking colour variants are possible – Yellow, Pink, Green and Orange – as well as countless applications.

TAYA Groups has officially launched the world’s first Eco Calculator for large-format banner materials, making it simpler than ever for businesses to evaluate and understand the eco savings of KAVALAN PVC-free banner and textiles.

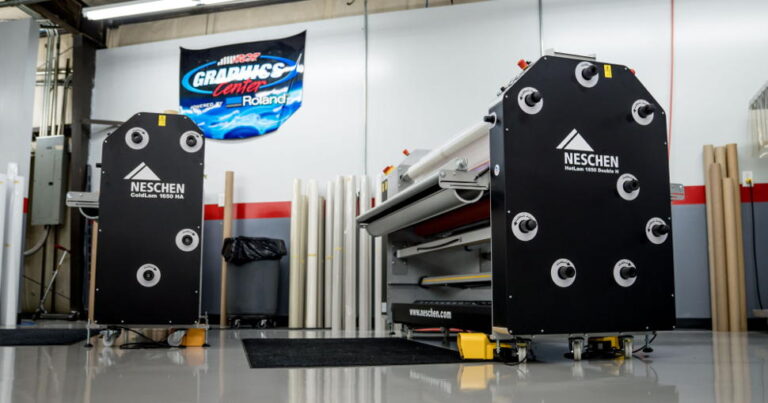

Neschen, the German manufacturer of self-adhesive media, laminators, and industrial coating solutions and its premier distributor of hardware in North America, Smooth Finish LLC, unveiled a multi-year partnership with Richard Childress Racing (RCR).

William Smith, part of William Smith Group 1832 are pleased to add yet another digital print film to their material portfolio, increasing customer’s choice even further.

Kernow Coatings, leading manufacturer of OEM certified printable digital synthetic papers, has announced that following ISO 21702:2019 testing (which measures antiviral activity on plastics and other non-porous surfaces) that KernowPrint HWT5 has shown to reduce SARS-COV-2* by 90% after 24 hours when compared to an untreated product.

William Smith, part of the William Smith Group 1832 are pleased to announce the addition of VinylEfx to their comprehensive portfolio of digital print films.