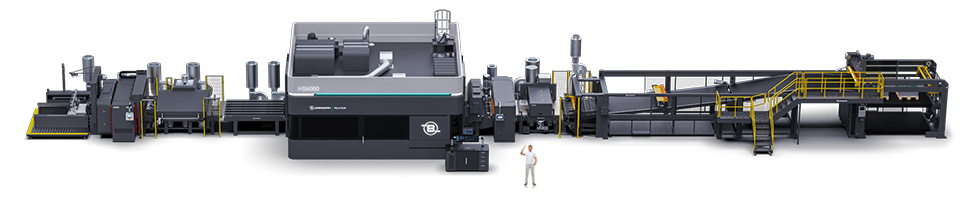

I’ve stood in front of a lot of wide-format printers over the years, but I’ve never stood *inside* a printer before. Yet here I am, inside a printer in the Barberán factory in Castelldefels, Barcelona. And frankly I’m a bit blown away by its sheer presence. The Barberán HS6000, or as it has recently been renamed, the Fujifilm Acuity Aristo HS6000 printer, is big. Very big. And built to last.

I’d never previously had to consider a digital printer with brackets and fixings made of 15mm thick steel – that might seem trivial, but it’s the first obvious clue to the build quality we’re seeing here. In fact, an Acuity Aristo printer impacts you similarly to the way an Airbus A380 leaves you wide-eyed when you see it for the first time; point being, everything you imagined is just bigger and heavier and altogether more imposing when you see it in the flesh.

So, who is Barberán?

The name Barberán might be new to some of you. Many in our industry hadn’t heard of them prior to the announcement of their 2022 development deal with Fujifilm, but they have pedigree.

Over the last 10 years, Barberán has established itself as a world leader in high-end, high productivity industrial presses for the corrugated market, with 30 customers in North America alone.

Barberán is even more dominant in the furniture market. Indeed, walk into a furniture manufacturing plant anywhere in the world and there will probably be a Barberán machine in use there. In this market the brand is almost a label, so synonymous with the technology that the brand has become a description of the process as a whole. In furniture manufacturing having “a Barberán” was a way of referring to an entire range of automated furniture manufacturing products covering lacquering, profile wrapping, lamination and – of course – now digital printing.

With customers that include some of the biggest furniture retailers in the world, including that one with the maze-like store layout, the pedigree of Barberán is clear, and their reputation fully earned. It also means that most houses in the UK, or anywhere in the world for that matter, probably have one or more items of furnishing produced on a Barberán.

That pedigree has history too; dating back to 1929 when the family business Barberán S.A. was established as a blacksmith and metal-working foundry. That manufacturing tradition carries through to today, where the current Managing Director, Jesús Barberán, presides over a facility that still manufacturers all of the metalwork of their behemoth printers in-house, with the proud mantra ‘100% Barberán, built to ISO 9001 Quality’.

Unparalleled build quality

The build quality is also something to behold. For example, the carriage that holds the printheads is manufactured to sleeve the printheads with piston tight tolerances. In real terms, this means that if a printhead goes down, the operator can change it and continue printing in minutes. There’s no need to recalibrate the printhead as the tolerance is such that no adjustment of the head is necessary. The head goes in exactly where the head came out, with zero margin for error. This is real. Spare printheads are included in the printer care kit.

That’s a big part of what is being done here by Barberán; from loading to feeding, from printing to finishing, keeping downtime to an absolute minimum by designing solutions where problems are engineered out from the get-go. Overall productivity is absolutely a by-product of the overall engineering quality.

Digital print performance in a nutshell

The key Acuity Aristo facts follow: Over 6,000 sq.m/hour, 1.6m print width, 5 picolitre droplet size capable of printing 3pt text and soft gradient effects, multiple 600dpi printheads for excellent quality even at top speeds, and optimised feeding that reduces gaps between prints. It handles media from 125gsm paper through to corrugated fibreboard, foamboard, display boards, poly sheets such as Coroplast and Polystyrene, and a whole lot more besides.

When compared to competing products, versatility is key here. And with productivity this high, and that investment cost to claw back, versatility means a broader range of profitable work being undertaken.

The applications that can be serviced by this printer are broad and open-ended, with material handling from thin sheets to heavy rigids, and an ability to print with strong adhesion to an almost limitless range of films and surfaces, the Acuity Aristo has created something of a niche for itself. I can’t think of another printer that currently competes in terms of what can be printed at this production volume. Suffice to say you won’t be turning very much work away, regardless of clients’ demands.

Where is the Acuity Aristo positioned?

This printer sits squarely in the gap between existing digital presses and a traditional offset press in terms of price and ROI. Where inkjet is typically expected to have a working life of perhaps 5-7 years and has to earn its keep within that span of time, the Acuity Aristo has a life-cycle estimated closer to 10-12 years (the first Barberán Jetmaster built is now 13 years old and is still in full-scale production). This is made possible by the industrial build quality, and in no small part by the pedigree and reputation of the two companies involved in bringing the Acuity Aristo to market: Barberán builds to industrial standards, while Fujifilm has a solid reputation for standing behind their products.

It’s also important to note that Fujifilm has an ability to bring additional ink developments, whether that be to meet changing compliance regulations or to further improve performance. It’s another viable and important benefit when considering the overall working life of the printer.

Who is the Acuity Aristo series for?

Where traditionally Barberán typically built one machine for one task, and it carried out that task all day every day, the new Acuity Aristo HS6000 – just like the one currently being installed at Linney in the UK – is going to have a far more varied and versatile life.

As already stated, the Acuity Aristo has been designed from the outset for volume and versatility. Corrugated boards, sure, but also paper and a broad range of materials – many requiring no primers or pre-coating thanks to the high adhesion Fujifilm UVijet inks.

Ultimately the Acuity Aristo range will support digitisation for some of the highest volume sign and display print production businesses in the world. It will provide a path to digital transformation for businesses printing such massive volumes that (until now) offset processes usually made more economic sense.

It’s perhaps when comparing an Acuity Aristo to installing a traditional offset press that the circa £4 million price of an Acuity Aristo no longer looks quite so daunting. The people installing one know what they want, why they want it and what it must deliver. And deliver it will.

I’ll try to paint you a scenario: you are running an Inca Onset digital press, and you’re operating shifts around the clock 24/7 to meet your clients print volume requirements. Installing an Acuity Aristo will increase productivity by a factor of multiples, allowing that same daily production quota to be completed in just a few hours.

A factory that was operating at capacity, in what was potentially a quite stressful environment, can now produce less frenetically, and everyone gets to go home at a sensible time. More print, less panic, lower costs. All with future production capacity in hand to expand exponentially.

For the right customer, the ROI is immediately obvious.

There’s an HS6000 being installed now at Linney in the UK

One such customer is Linney, a full-service UK-based marketing agency, who have become the first company in the world to invest in this new, ultra-high productivity, single-pass Acuity Aristo. At the time of writing, it is in the process of being installed.

Charles Linney, part of the sixth generation of the Linney family working in the business, sees their Barberán – or Acuity Aristo – (sorry I haven’t got used to the name change yet) investment as hugely significant: “The Acuity Aristo really does feel like a huge step forward and will help us cater for the ever-increasing speed to market that our clients need.

“We strongly feel that the time for single-pass inkjet is here; we wanted something with reliability, speed, quality and excellent up-time in equal measure.

“On all these measures, the Acuity Aristo has hugely impressed us. It’s 5-10 times faster than our previous Inca digital technology, the quality is fantastic, and our operators have been mightily impressed.

“We’re excited to be investing in this press, and we’re delighted that it will be Fujifilm and Barberán partnering with us as we do that. Both have been fantastic to work with.”

A baby Barberán: cuter and more affordable, but still a monster.

At the more affordable end of the scale – more comparable to the price you’d expect to pay for an Inca or Durst commercial digital setup – sits the Acuity Aristo HS3000.

Barberán designed this narrower HS3000 printer with a straightforward alignment system – adapted from their proven flooring technology, along with an inline coating unit to deliver a satin finish.

A leading online signage company in the US has just signed off on an investment on the first HS3000. They required a machine capable of printing onto 800mm wide boards, with a focus on simplicity and speed rather than automation – and that is all it will do, all day, every day, fast as you like. That’s exactly the type of scenario for which an Acuity Aristo HS3000 is designed for.

Indeed, the specific production requirements of this customer were a perfect fit for Barberán’s expertise in tailored machine design. Combined with the wide adhesion range of Fujifilm’s Uvijet HS inks, it enables the customer to print across a variety of rigid plastic substrates at jaw-dropping speeds, and without the compromise or added cost of primers.

This particular HS3000 machine was signed off in Barcelona in July and will enter production in the USA in the near future. Of course, we’ll bring you more news on that as it happens.

Barberán and Fujifilm: fantastic to work with, exceptional together.

Eladio Lerga, Technical Director of Barberán adds: “We’re really excited to be bringing our technology to a whole new market. Fujifilm’s breadth of experience in print for sign and display will be crucial to this – as well as its expertise in inkjet ink chemistry and inkjet systems. Working together we can maintain our print speeds and quality and adapt our systems to accommodate a much wider range of substrates and to meet the very different market requirements of the sign and display sector.”

David Burton, Business and Commercial Director at Fujifilm WFIJ HQ, says: “We choose our partners carefully and Barberán is no exception. We were in close talks with them for more than two years because they have a huge amount of expertise in industrial print manufacturing and we saw an opportunity for a mutually beneficial relationship. They already had a single pass product that is proven in the corrugated sector, and we had the expertise to help them adapt it for the very different requirements of the sign and display market.

“Fujifilm has a huge market presence across the whole graphics sector, from analogue to digital,” Burton continues. “It’s a market presence that spans commercial print and packaging, as well as sign and display which, of all the graphics sectors, has digitised most rapidly in the last two decades. We’ve played a key role in that transformation, and, with this project, we can take that process on to a new level again.

“That breadth of experience, and our unrivalled expertise in ink development, combined with Barberán’s skill in heavy engineering, makes us the perfect partnership to provide a business development opportunity for high-end flat sheet sign and display printers”

To find out more about the Acuity Aristo please visit the product lines dedicated website at https://acuityaristoseries.com