Wide Format Print

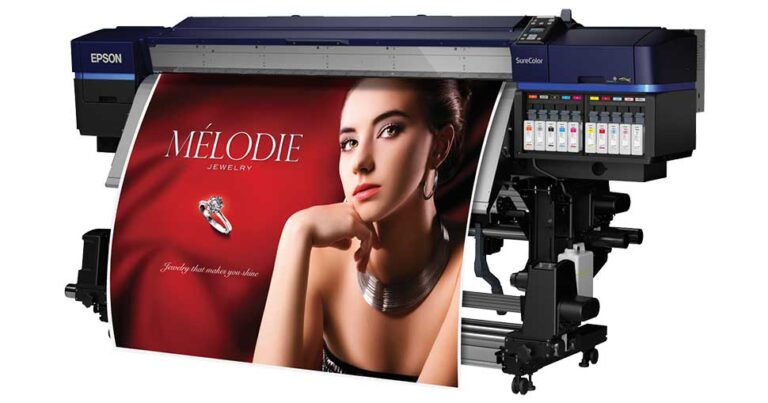

Three of Epson’s latest SureColor large format printers have been awarded Buyers Lab (BLI) 2022 Wide Format Pick Awards.

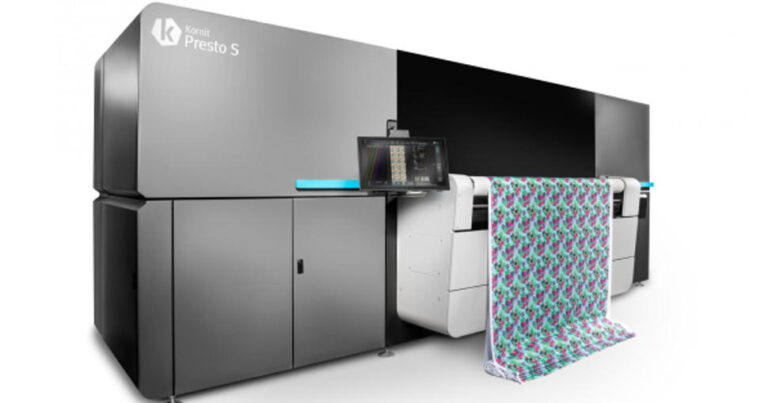

Kornit Digital Ltd., a worldwide market leader in sustainable, on-demand, digital textile production technologies, announced today that Portuguese textile specialist Blur has installed the Kornit Presto S with Softener solution for sustainable, single-step direct-to-fabric production of multiple fabrics in any quantity.

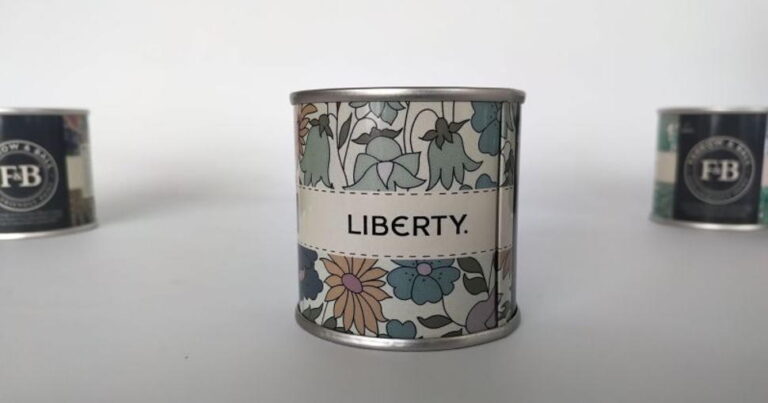

Luxury homeware brand Liberty and paint manufacturer Farrow & Ball have collaborated to launch a range of limited edition tin designs, which were printed using Fujifilm’s Acuity B1 digital press.

From its beginning as a school reprographics department to a fully-fledged commercial printer, a key aspect of the journey for Park Community Enterprises is its partnership with Ricoh. That relationship has helped develop a thriving business and met the founding principle of marrying education and enterprise.

Pittsburgh-based Fotorecord Print Center (Fotorecord), a 20-employee printing company with a 28-year history, recently transitioned from traditional offset print equipment to an all-digital print environment with the installation of a FUJIFILM J Press 750S digital Inkjet press (J Press).

With the installation of an Avinci CX3200 sublimation printer, Publi-FDM, located in Sint-Lievens-Houtem (Belgium), is getting a global first.