Industrial Print

Electronics For Imaging, Inc., hasreported that Serigraph, located in West Bend, Wisconsin, has acquired an EFI Q3h XP hybrid LED printer to boost productivity and ensure accuracy for color-critical applications.

Following Mutoh Europe’s launch on September 10th, Graphtec GB has confirmed that the XpertJet C641SR Pro will be on its stand at The Print Show. This 24” (630 mm) wide printer is Mutoh’s first-ever integrated print-and-cut machine.

Kongsberg Precision Cutting Systems (Kongsberg PCS) has today (September 10) unveiled the latest evolution of its flagship MultiCam Apex3R CNC router, raising the bar for superior quality and signalling a new era in high-performance routing capabilities.

LAS VEGAS (PRINTING United Booth #SL8101) – Building on the success of its acclaimed SureColor S-Series signage printer line, Epson has announced the next-generation SureColor S9170.

Canon has announced the addition of its FLXflow technology to the Arizona 1300 series, which brings new productivity and performance features to the flatbed printer series.

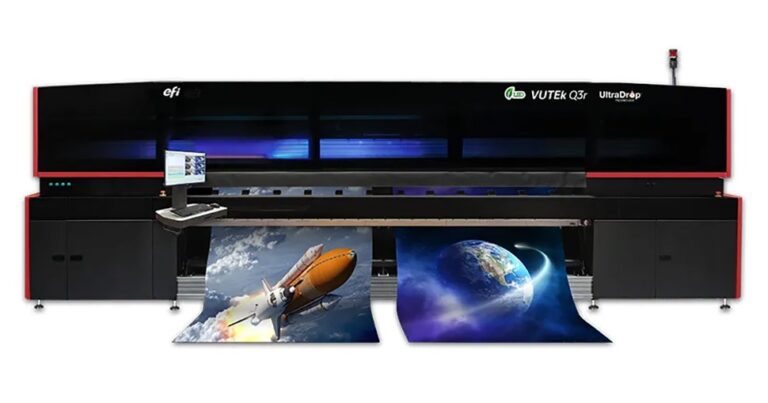

Electronics For Imaging, Inc. has reported it is exhibiting its newest production-level digital inkjet printers, and displaying brilliant applications and samples produced from their broad portfolio of sign and display graphics, packaging, and textile printers at the PRINTING United Expo, running September 10-12 in Las Vegas. EFI is in booth SL7005 at the show.