Wide Format Print

Wide-format digital imaging leader Roland DGA will demonstrate the impressive capabilities of its newest devices, display stunning samples of output produced by these machines, provide advice on expanding into lucrative new markets, and conduct live vehicle wrap demonstrations at the 2024 PRINTING United Expo, September 10-12, in Las Vegas.

As Wrexham AFC’s Global Technology partner, the football club have worked with long term HP customer, PressOn, one of the UK’s leading Large Format Print firms, for the design and installation of new graphics within the STōK Cae Ras football stadium.

Bear’s Detailing recently invested in a Graphtec FC9000 cutter from Granthams GT to improve its cutting capability. Tony explains, “We faced significant delays in receiving pre-cut materials on time, which significantly impacted our overall workflow. If we then had any issues with the cuts, it meant additional delays due to extra delivery times.”

HP is delighted to announce that it will be the Headline Print Partner for the UK edition of the World Wrap Masters competition at the upcoming FESPA WrapFest 2024 showcase.

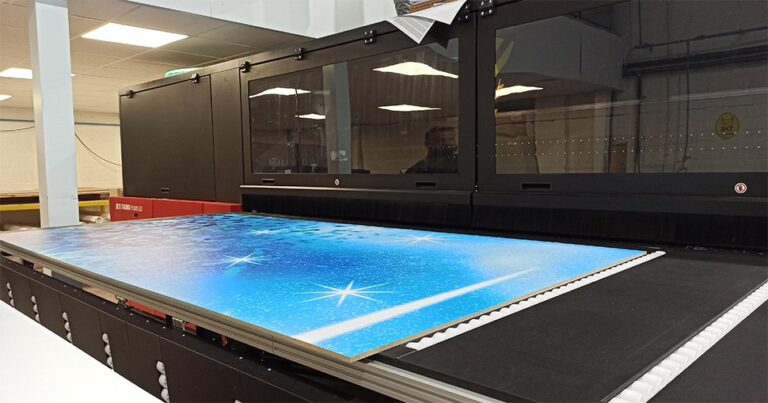

In the ever-evolving world of print, innovation is key to staying ahead within the industry. At FaberExposize UK, we pride ourselves on pushing the boundaries of what's possible in wide-format printing. One of the most exciting developments in our industry is the ability to print on 'untraditional' media using large format AGFA inkjet solutions, such as the Jeti Tauro.

Specialist arts and commercial printer John Good has revealed its investment in an HP Latex R2000 printer 12 months ago has allowed the company to expand into new markets and grow its customer base.