Textile Printing

Ricoh, a global leader in digital textile printing, has significantly advanced apparel decoration and customisation with its latest innovation in Direct to Garment printing technology, the new RICOH Ri 1000X.

Label Express, a front runner in LED digital production technology and celebrating its 40th anniversary, sees business growth in all sectors after its investment in a Tau 340 RSC-E LED single-pass label press from Durst Group, manufacturer of advanced digital printing and production technologies.

Leading innovator in inkjet technology Xaar has launched two new printheads, the Xaar eX and Nitrox eX, specifically designed for coating the new generation of batteries used in electric vehicles (EVs) and energy storage systems.

Kartongbolaget, a leading Swedish provider of high-end packaging solutions, has invested in Fujifilm’s Jet Press 750S at drupa 2024 to advance its packaging capabilities, while prioritising sustainability.

Global technology company, Epson, is adding two new 64-inch dye-sublimation printers to its successful line-up of top selling 64-inch dye-sublimation printers for Europe.

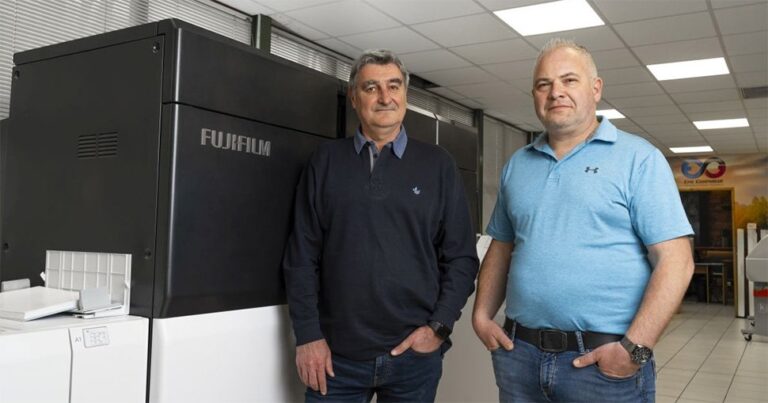

Established in the mid-1980s, Imprimerie RGI is a leading commercial print business with a well-deserved reputation for delivering exceptional quality and customer service, with the company’s investment in the Jet Press 750S High Speed Model and Revoria Press PC1120 delivering multiple benefits in terms of quality and productivity.