Industrial Print

Spanish printing giant Oedim has significantly increased its printing capabilities through its continued partnership with Fujifilm and further investments in the company’s wide format printers.

Two Mimaki industrial UV printers sit at the heart of Skelmersdale-based sign maker, Origin Sign Co’s kit list and are allowing the forward-thinking business to target new markets as it expands its operation with new applications and products.

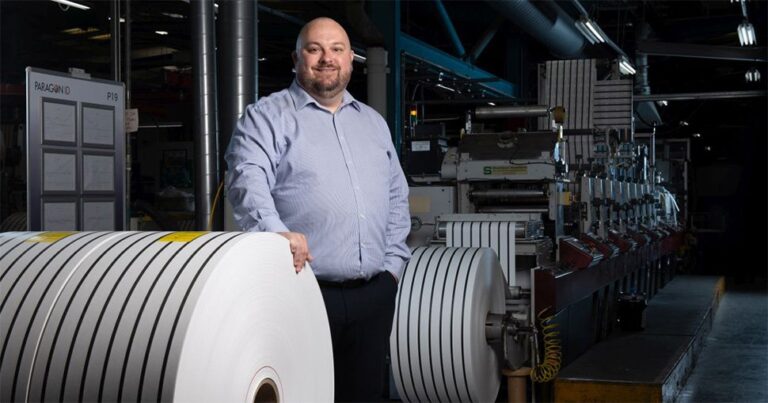

Paragon ID UK, a global leader in identification solutions, has invested in LuXtreme, Fujifilm’s LED UV curing system, and CuremaX, Fujifilm’s LED UV inks.

Sappi Europe, a global leader in paper-based packaging solutions, has made significant advancements in its flexible packaging papers division.

Ricoh, a global leader in digital textile printing, has significantly advanced apparel decoration and customisation with its latest innovation in Direct to Garment printing technology, the new RICOH Ri 1000X.

Label Express, a front runner in LED digital production technology and celebrating its 40th anniversary, sees business growth in all sectors after its investment in a Tau 340 RSC-E LED single-pass label press from Durst Group, manufacturer of advanced digital printing and production technologies.