Print Finishing

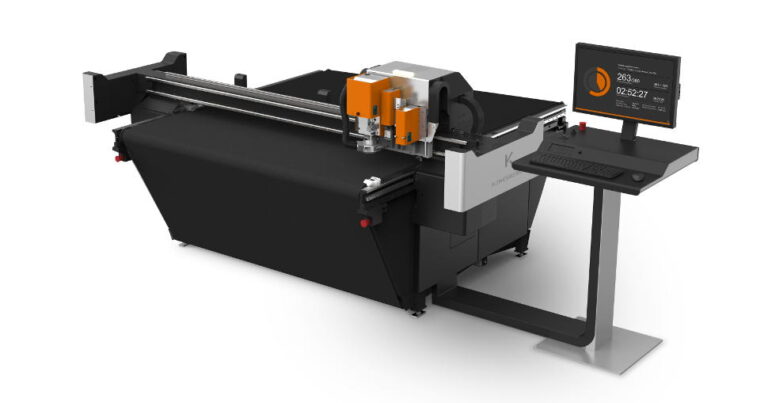

Kongsberg Precision Cutting Systems (Kongsberg PCS) has today announced the expansion of its C Series range of digital finishing tables with the launch of the compact new C20 – the smallest high-speed production table on the market.

For most 15 year olds, the prospect of driving their own car is still a distant dream, but for Max Dodds, it’s practically become a full time job. A racing driver since the age of four, Dodds is preparing for his first season in the highly competitive Ginetta Junior Championship – a proven feeder series for GT, Touring Cars, Formula One and other higher echelons of the sport – in a car that’s been wrapped to maximise its aerodynamic performance.

Cutting acrylic glass is an art form in itself. It is not just cleanliness at the processing station or reworking of the cut edges that make the material demanding. Besides, there are two completely different versions of acrylic glass that are relevant for laser cutting: extruded and cast.

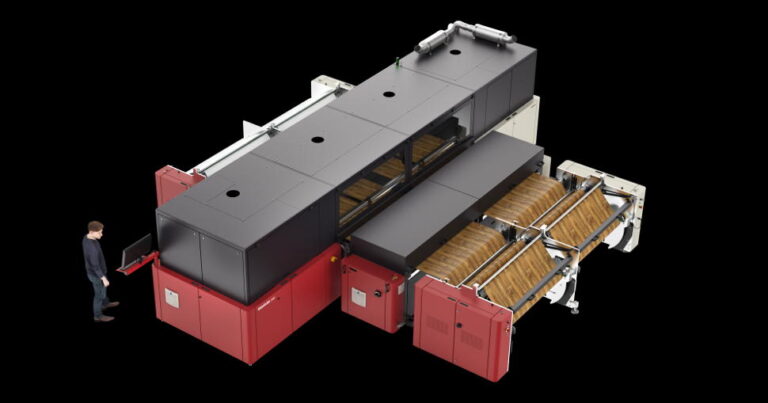

Slotex, a leading Russian supplier of decorative laminate solutions, recently installed Agfa’s InterioJet water-based inkjet printing engine. The InterioJet enables them to provide a high level of reliable service for each client.

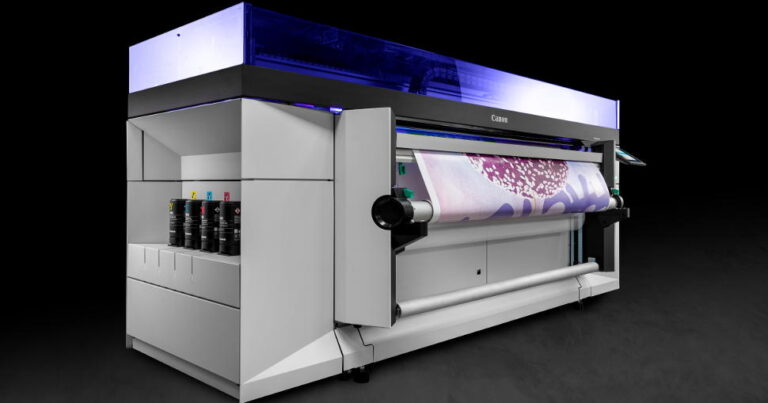

Building on its portfolio of 64” UVgel roll-to-roll printers, Canon today announces the launch of the new Colorado 1630, which will give customers access to all the advantages of UVgel technology at a lower investment.

Northumbria University has paid a special tribute to the impact of its HP Stitch S300 dye sublimation printer, revealing that the device has played a key role in allowing students to continue learning and working during the pandemic.