Business News

Fujifilm’s revolutionary AQUAFUZE water based UV ink was commercially launched along with the 1.6m Acuity Triton printer at FESPA 2025.

Bill is an experienced leader who will help to drive Inkcups' future growth as the company continues to innovate, create value for customers

The acquisition from Ricoh Company, Ltd. strengthens Print ePS’ position in the midmarket print segment.

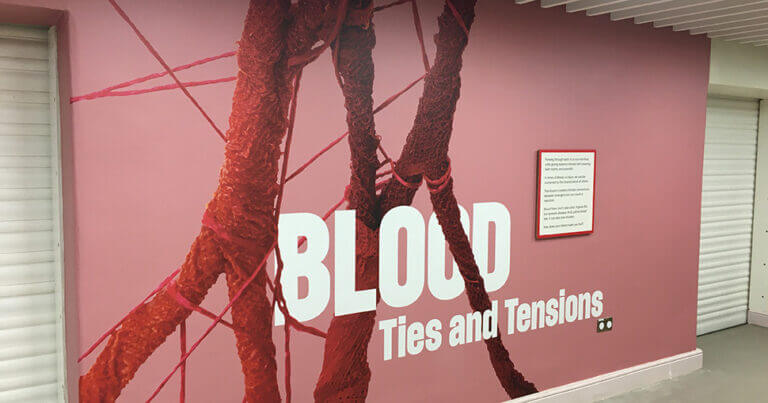

Digital Plus used Kavalan Gecko for the wallcoverings. This paste-the-wall grey-backed textile is available in widths of up to 5m.

Xavi Regue has been appointed as the new Vice President, Go-to-Market for HP’s Large Format business, effective June 1, 2025.

Despite misconceptions, a growing number of consumers understand the facts about Europe’s forests and the environmental credentials of paper