To find out more about the new product, as well as Digidelta’s other solutions and the company as a whole, LFR sat down for a special interview with CEO Armando Mota for an exclusive insight into the diversified materials supplier, its brands – including BIOND and Decal – and its plans for expansion moving forward.

LFR: Can you give us some background on Digidelta? How did it get to become the business it is today?

Armando Mota: Digidelta was founded in 1986 by Rui Leitão, who continues to lead the company as Chairman. We started out as a small technology integrator, working closely with clients in Portugal to deliver digital imaging, printing and visual communication systems.

A key turning point came in the early 2000s when we became the official distributor of Mimaki in the Portuguese market. This opened the door to a new chapter, expanding our service beyond delivering just equipment to supporting a full printing ecosystem.

In 2006, we launched our own brand of media, decal, which was created based on the feedback of real customers. Printers needed adhesive films that were easier to apply, more reliable to print on, and more cost-effective. What started small quickly gained traction across Europe.

By 2010, we had built our own industrial and logistics hub in Torres Novas, Portugal. It houses our coating and converting unit, R&D lab, distribution centre, and training showroom, all under one roof. This was a turning point that allowed us to control our quality, innovate faster and serve key global markets directly.

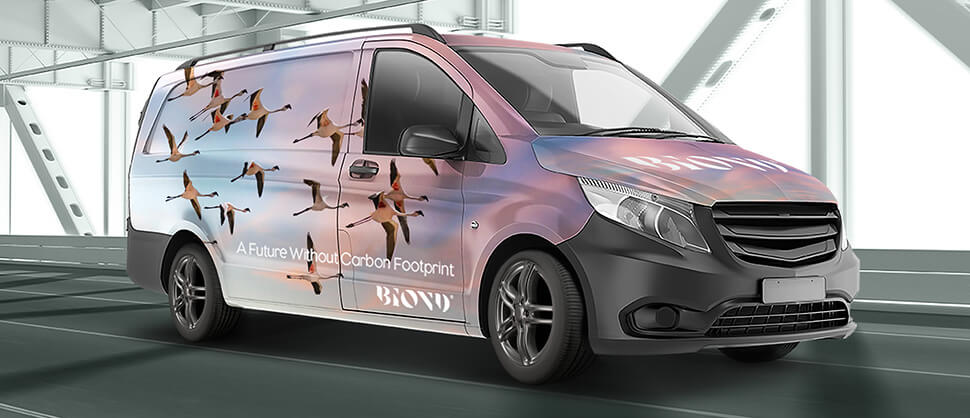

Between 2022 and 2024, we invested heavily in R&D to create a new generation of sustainable films. This resulted in the launch of BIOND films in 2025 at the FESPA Global Print Expo in Berlin to great acclaim. BIOND is a bio-based, true PVC-free brand that brings together design, environmental responsibility and industrial performance.

Today, Digidelta exports to over 60 countries, and our brands support thousands of professionals in print, signage, décor and retail environments.

LFR: What does the current setup of Digidelta look like?

AM: We currently have over 150 professionals across multiple departments, spanning R&D, production, logistics, marketing, international sales, and technical service. Our structure is designed to deliver complete solutions, combining industrial capability with proximity and technical expertise.

Our core facility is the production and logistics hub in Torres Novas, Portugal, which covers an area of more than 15,000sq m. On-site facilities include four high-performance coating lines that enable the production of over 75 million linear meters of adhesive materials per year; six slitters converting semi-finished jumbos into finished rolls, allowing us to hit 100 million sq m/year; 1,300 storage racks with capacity for 8.3 million sq m of semi-finished stock; in addition to a technical and quality lab, demo showroom and training centre.

This infrastructure supports our global operations, with a strong presence in Portugal, Spain, and a fast-growing international distribution network. We also run showrooms in Lisbon, Porto, Madrid, Barcelona and Seville to offer local support to customers, with each equipped for live demonstrations and technical training.

On top of this, we have secured several certifications to demonstrate how Digidelta and its brands meet the highest industry and environmental standards. These include the ISO 9001:2015 quality management standard, R9 Anti-Slip classification for floor graphics (DIN 51130:2014), and FDA approval for food and human contact materials.

LFR: What core challenges has the business both faced and overcome? What have been its biggest achievements?

AM: Like many industrial companies, we have had to adapt to rapid technological changes, global crises, and evolving environmental regulations. One of our biggest challenges was transitioning from being a distributor to a fully integrated manufacturer; building our own production unit, managing quality and investing in innovation was no small feat.

Another major challenge was responding to growing demand for sustainable alternatives without compromising performance. We overcame this by creating BIOND, a high-performance, bio-based alternative to PVC films, with the look, feel and functionality that professionals demand.

Our most significant achievements reflect how we transformed those challenges into new growth opportunities. These include building a portfolio of trusted brands, such as decal, known for easy application and outstanding print results, and developing Dot Matrix and Bubble Free technologies to simplify installation.

On a wider scale, I would say the fact that we have established a global presence, with exports to over 60 countries, as being one of our core achievements. Of course, this was helped by last year’s investment in our decal® 4.0 factory, which has tripled our production capacity and integrated automation from coating to packaging.

These milestones were only possible thanks to continuous investment in innovation, a strong commitment to technical excellence, and a team determined to push boundaries and lead in every market we serve.

LFR: Switching focus to your solutions, what would you say are the unique selling points of Digidelta products?

AM: What truly sets us apart is our ability to create products that simplify professionals’ work while meeting the growing demands for sustainability and quality. Our two brands — decal and BIOND — reflect this dual commitment.

With decal, innovation means usability. We developed technologies such as the Bubble Free and Dot Matrix adhesives, which allow bubble-free, repositionable, and residue-free application – even by non-professionals. This helps to reduce errors, cut labour costs and speed up installation.

We also work with double-sided PE liners, which prevent curling and eliminate waste between printing jobs. They keep the media stable and flat during production, protecting printheads and improving reliability.

Our overlaminate High-Tack UV adhesives offer strong, solvent-free bonding with high transparency, ideal for UV and latex printing without any silvering, while we also use high-qualityPVC films that are EU certified.

As for our BIOND range, we see this as our boldest step towards the future. It is a new generation of bio-based films with over 85% renewable content. For us, what makes BIOND unique is that it combines eco-consciousness with high performance; to put it simply the material behaves like traditional vinyl. It stretches without tearing, making it ideal for print and cut, and it comes in premium textures like wood, stone or canvas for interior decoration markets, offering customers a much wider choice of options.

We also apply the same Dot Matrix and High-TackUV technologies to BIOND, maintaining ease of application and bubble-free results. In addition, as we use a bio-based polymer, the carbon footprint is significantly lower, with BIOND producing over 80% less carbon dioxide emissions than PVC. Add in that it is fire rated (B-s1, d0), anti-slip certified for floors (R10), and safe for food contact in certain applications, and this opens up all manner of opportunities to users.

LFR: Looking to the future, what are your main hopes and goals for the business?

AM: We are very much centred on continuing to lead through innovation with purpose. We want to develop solutions that are not only technologically advanced but also practical, sustainable and aligned with the real challenges faced by professionals.

A major focus is on the global expansion of BIOND films. After years of R&D and validation, BIOND is now ready to scale and we’re working to grow its presence across international markets, especially among brands and professionals seeking high-performance alternatives to PVC. With its certified sustainability credentials and vinyl-like usability, BIOND will redefine how the industry approaches eco-friendly media.

In this next phase, we’re also expanding the BIOND portfolio with new lines for labelling and flexible packaging, addressing the increasing demand for sustainable materials in the packaging industry. At the same time, we’re launching premium decorative films, including textured and printable solutions for walls, furniture and retail interiors, combining aesthetics, durability and eco-consciousness.

Alongside this, we’re investing heavily in reinforcing the decal brand, pushing the boundaries of what usability and reliability mean for printers, installers and resellers. That includes continuous innovation in adhesives, liners and coating performance, all developed and tested in-house.

We also believe in empowering people through knowledge, which is why we’re currently developing the Digidelta Academy, offering live workshops, hands-on training sessions and demo experiences both on-site and through our international showroom and partner network.

In addition to all of this, we remain deeply committed to reducing our environmental footprint. From sourcing raw materials to coating, converting and distribution, we’re rethinking every step of the process to become more efficient, less wasteful, and more responsible.

LFR: Similarly, where would you like to see the company in five, 10 and 20 years?

AM: In five years, we envision BIOND as a leading name among creative professionals, designers and brands looking for high-performance, sustainable films. We want it to be recognised not just for being PVC-free, but for combining aesthetics, printability and responsibility in one solution. We also aim to give more people access to this technology — democratising bio-based films so they become a realistic, desirable option for a much broader market.

At the same time, we see decal continuing to strengthen its position as a trusted brand for printers, installers and resellers across the world, especially for its ease of application, anti-humidity liner technology and wide compatibility with digital printing.

In 10 years, our ambition is for Digidelta to be a global reference in sustainable printing and visual communication materials. We are already a recognised leader in the Iberian market, and we aim to consolidate that position while expanding the company worldwide.

This includes entering new industries where eco-design is key, such as retail, architecture, interior branding and packaging, as well as developing closed-loop solutions that contribute to the circular economy, reducing waste and extending product lifecycles.

We also expect BIOND to gain stronger presence across multiple sectors such as packaging, labelling, branding and product design, becoming a mainstream choice for innovation-driven professionals and sustainability-conscious brands.

In 20 years, we aim to be a global benchmark in ESG-driven industrial innovation. A company with an agile, scaleable production model, present in new territories and actively shaping how materials are designed, applied and recycled. A partner of choice for those that value technical performance, environmental commitment and strategic collaboration, helping redefine the future of visual communication through materials that make a difference.

LFR: Beyond all this, what else are you doing to support customers?

AM: At Digidelta, we’re not just producers of materials or distributors of equipment; we’re builders of ecosystems where innovation, usability and sustainability come together to support professionals and brands in meaningful ways.

Beyond our product lines, we’ve developed complete solutions that respond to real market needs. These include financial tools to allow clients to scale without overburdening their cash flow; as well as integrated application workflows where media, hardware and training work seamlessly; multi-lingual commercial and technical support, and co-branded marketing tools and customer support.

We’re also deeply committed to advancing the next generation of sustainable print materials. This includes investing in recycled-content films and water-based adhesive technologies; achieving international certifications across quality, safety and sustainability; and developing partnerships focused on circular economy models and low-carbon production.

We’re proud of what we’ve built, and even more excited about what’s to come, always guided by the same values: quality, responsibility and progress.