Events

At Booth 2004, the Chamber of Automation guides visitors on a magical journey to rethink digital workflows and discover automation wizardry.

Andy Thomas‑Emans, Strategic Director at Informa Labels & Packaging, outlines why the landmark show is being rebranded as LOUPE.

Tecnau (Booth 2621) and Sitma will showcase three live production lines with cutting-edge digital print finishing and packaging solutions.

Berger Textiles, part of the Spandex Group, is globally known for its high-quality, innovative grand format textiles, 126” and wider.

UFABRIK Wallcover Eco Canvas is sustainable, reusable, and recyclable, made from at least 80% SCS-certified recycled plastic bottles.

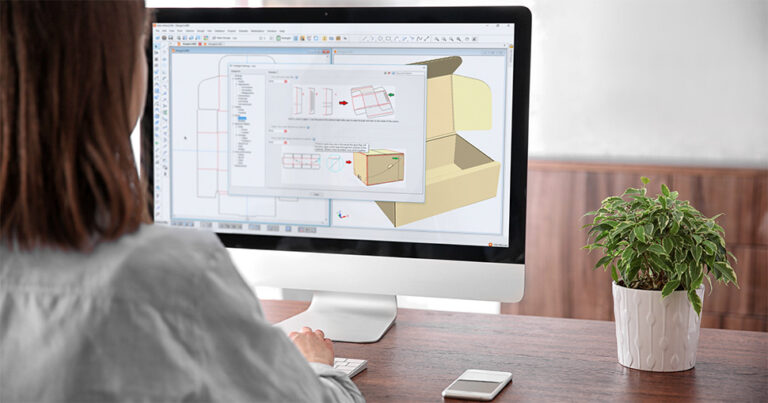

From booth 08.M49 in Hall 8 of the Messe Frankfurt, Esko will also showcase how Esko Studio brings packaging design to life in 3D.